Closing the Experience Gap: How LOTO Software Helps Protect Against Vulnerabilities

Moving safety to the point of use

One of the most effective ways to eliminate the "search" for safety information is to move procedures from the back office to the equipment itself. In a traditional setup, a maintenance worker might have to track down a physical binder or search through a digital directory structure that mimics a computer file system — sorting by site, area and equipment type to find the right document.

For new or covering employees who don’t know the machine, the search process introduces the potential for error and non-compliance. If the printed lockout procedure is outdated, inexperienced employees are less likely to notice the error.

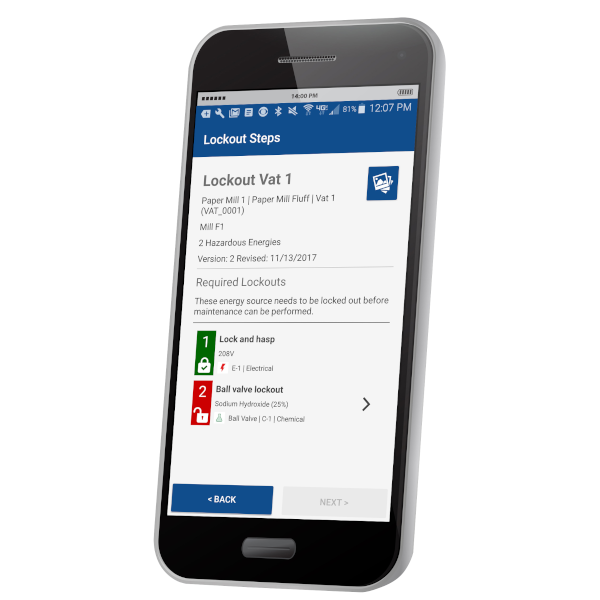

Mobile technology streamlines the search process with QR codes or RFID tags physically attached to the machinery. By scanning a code located directly on the piece of equipment, the worker is instantly presented with the specific lockout procedure. This ensures that the employee is always viewing the latest version of the document, rather than an outdated printout or an obsolete file version saved on a laptop.

Providing real-time validation

Locating the procedure is only half the battle; locating the correct energy source is where critical errors often occur. For example, a worker might enter a motor control room and face a bank of five or six identical disconnect panels. Without intimate knowledge of the facility, identifying the correct disconnect can be difficult. Some safety solution providers offer a mobile software solution that provides visual validation to address this risk. As the worker progresses through the lockout steps, they can scan the identification tag on the specific isolation point (such as a valve or breaker). The application provides immediate visual feedback:

- A green box: Validates that the worker is at the correct isolation point and allows them to proceed

- A red box: Alerts the worker immediately that they are attempting to lock out the wrong device

This digital validation acts as a guardrail, preventing workers from applying locks to the wrong energy sources due to confusion or lack of familiarity with the area.

Ensuring the "two-week" benchmark is met

Digitizing LOTO procedures helps separate safety competency from tenure. A robust safety system should allow an employee who has been on the job for only two weeks to use authorized lockout devices and perform a lockout as safely and accurately as a senior technician.

By utilizing mobile devices that display clear, annotated photos — such as images with arrows explicitly pointing to the correct disconnect switch — and combining them with scan-to-validate technology, facilities can level the playing field. The software provides the guidance and confirmation that a mentor typically would, ensuring that a lack of experience does not result in a safety incident.

Providing mobile access with or without internet

A common objection to adopting mobile technology in industrial environments is the reliability of internet access. Many facilities have basements, mechanical rooms or remote corners that act as dead zones.

Dead zones don’t need to be an issue though. Modern software platforms are designed to function independently of active internet connections. Workers can download the necessary procedures and work orders to their devices while in an office or connected area. They can then proceed to the area with limited access, perform the lockout, input their data and complete the work offline.

Once they return to an area with connectivity, the device syncs the data back to the central system. This eliminates the "paper trail" problem, ensuring that all lockout activities are time-stamped and logged without requiring a live connection at the point of work.

Build a safety net for employees

Technology does not replace the need for fundamental safety training, but it acts as a critical safety net that standardizes execution. By digitizing the LOTO process, facilities can ensure that safety compliance is consistent, repeatable and completely independent of who is working the shift. Safety should never be left up to chance, and adding safeguards ensures that new employees can stay just as safe as the ones with years of experience.

Brady provides the products and the expertise to help you create a complete lockout tagout solution. Contact us to learn more.

Contact Us